An Attrition Abrasion Tester is a specialized instrument used to evaluate the resistance of materials to wear, abrasion, and attrition. This type of tester is commonly employed in industries such as manufacturing, materials science, and quality control to assess the durability and wear characteristics of various materials. Here are key features and aspects associated with an Attrition Abrasion Tester: Principle of Operation: The tester subjects the material under evaluation to repeat....

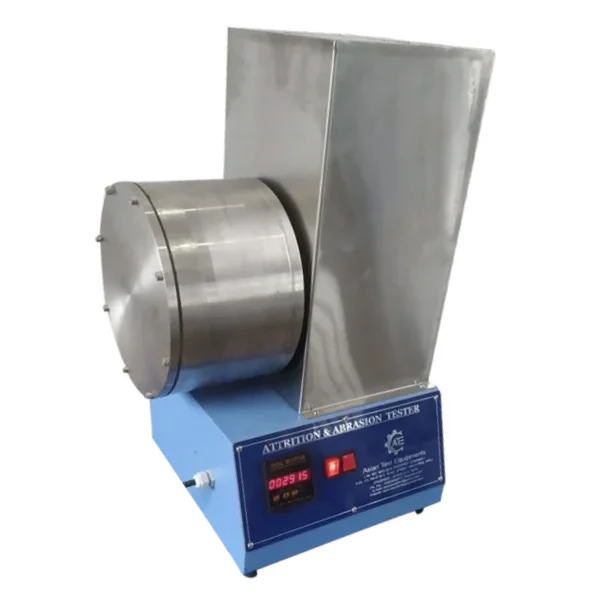

An Attrition Abrasion Tester is a specialized instrument used to evaluate the resistance of materials to wear, abrasion, and attrition. This type of tester is commonly employed in industries such as manufacturing, materials science, and quality control to assess the durability and wear characteristics of various materials.

Principle of Operation: The tester subjects the material under evaluation to repeated cycles of abrasion or attrition, simulating wear and tear that materials may experience in real-world applications.

Rotational Motion: Many attrition abrasion testers involve a rotating drum or a similar mechanism that imparts abrasion to the specimen. The drum may contain abrasive particles or other materials to induce wear.

Sample Holder: The instrument typically has a sample holder or chamber where the material specimens are securely mounted for testing. Proper sample preparation and mounting are crucial for obtaining accurate and repeatable results.

Abrasive Particles: Depending on the testing requirements, the tester may use abrasive particles or media to induce wear on the material surfaces. The choice of abrasive material can vary based on the application and the materials being tested.

Controlled Parameters: The tester allows for the control of various parameters, such as the rotational speed, duration of testing, and the applied load or pressure on the specimens.

Testing Standards: Testing procedures and parameters may follow industry standards or specific protocols outlined by organizations such as ASTM (American Society for Testing and Materials) or ISO (International Organization for Standardization).

Data Logging and Analysis: Modern attrition abrasion testers may include features for data logging, allowing users to record and analyze wear data over time. This helps in understanding material performance and making informed decisions.

Visual Inspection: After testing, specimens may undergo visual inspection to assess the extent of wear, surface damage, or other characteristics. Visual observations complement quantitative measurements.

Materials Compatibility: Attrition abrasion testers are versatile and can be used to assess the wear resistance of a wide range of materials, including metals, polymers, ceramics, and composites.

Quality Control: Manufacturers often use attrition abrasion testers as part of their quality control processes to ensure that materials meet wear resistance requirements for specific applications.

Safety Features: The tester may include safety features such as emergency stop buttons, protective enclosures, and mechanisms to prevent injury during operation.

Attrition abrasion testing is valuable for predicting the performance and lifespan of materials in applications where wear is a critical factor. It helps engineers and researchers understand how different materials respond to abrasive conditions, leading to improvements in material selection and design.

Corrosion test chamber is a great laboratory test equipment widely used in metal...

Cyclic Corrosion Salt Spray Chamber manufactured by Sigma Machines – the world...

Sigma Machines CASS tester is designed keeping in mind the relevant tester stand...

Ensure the quality and durability of your materials with our reliable Double Hea...

SIGMA Machines is counted among the best salt spray chamber manufacturers in Ind...

Enhance your testing capabilities with our advanced digital pounding tester...

Enhance your foam testing process with our advanced PU foam Indentation Hardness...

Enhance your yarn quality control with our reliable and efficient yarn strength ...

Get accurate results with our Shear Fatigue Tester for PU Foam...

Ensure precise measurements of soft materials with our reliable thickness gauge...

Enhance your understanding of ball performance using our reliable Ball Resilienc...

Asian Water Absorption Tester is Water Resistance Tester For Sole Leather- (Perm...

Discover the ultimate laundry solution with Laundrometer Digital Model - the per...

Enhance your testing process with Test Template D and achieve accurate and relia...

Ensure the safety of children's toys with our reliable and efficient flammabilit...

The humidity test cabinet provides a sample with the humidity that the materials...

Ensure accurate results with our advanced Bundesmann Apparatus Tester for compre...

A Hot air oven is a great tool for manufacturers to accurately test materials i...

hydrostatic testing equipment used for testing lateral pipes is located within a...

Enhance belt quality control with our Belt Flex Tester, providing accurate and r...

Rockwell Hardness Tester models are suitable for accurately testing the hardness...

Martindale abrasion machine is suitable for testing the pilling degree and abras...

Adhesion Strength Tester serves the purpose of measuring the peelability or perm...

ASIAN Bursting Strength Tester Machine is especially useful for measuring the pa...

Achieve superior strength and resilience with our cutting-edge tensile strength ...

Enhance your quality control processes with our reliable Impact Tester, providin...

Ensure accurate measurements of your drapes' performance with our reliable Drape...

Glow Wire Test Equipment is an important testing equipment which is used in the ...

The heat distortion temperature of the polymer in the test is identified as the ...

Range: 2000 lbs with 1 lbs least count digital display Elongations: Up to 9...

Torque Tester for Bottle Caps is one of the important instruments to calculate t...

The “ASIAN” Universal testing machine provide a relatively inexpensive way...

Asian Melt Flow Index Tester helping evaluate the flow properties of melted plas...

Size of the Test Specimen: 40 X 15 mm Distance between edge of the Crease...

Box Compression Tester is used to measure the box compression strength (BCT), sh...

Enhance your material testing capabilities with the advanced Demattia Flex Teste...

Enhance your understanding of material properties with our Oscillating Disk Rheo...

Enhance your scientific experiments with our Specific Digital Gravity ...

Looking for an accurate and reliable IRHD Rubber Hardness Tester? Look no furthe...

Explore the world of direct reading specific gravity balance through our informa...

Enhance your testing efficiency and accuracy with our state-of-the-art universal...

Discover the Cone Calorimeter Tester: Enhance fire safety with accurate and reli...

Enhance your testing capabilities with a state-of-the-art dry sand abrasion test...

.jpg)

Get In Touch With Us

See How your Business Can benefit With

Sigma Machines

Get Estimated Quote