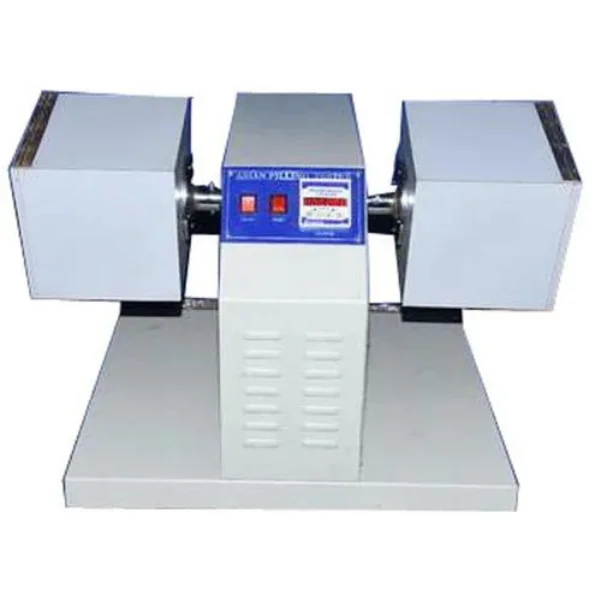

A Digital Pilling Tester is a device designed to assess the propensity of fabrics to form pills or fuzz on their surface. Pilling is the formation of small, fuzzy balls or clusters of fibers on the surface of a fabric due to friction, abrasion, or wear. The Digital Pilling Tester provides a standardized method to evaluate and compare the pilling resistance of different textiles. Here are key features and aspects of a Digital Pilling Tester: Principle of Operation: The Digital....

A Digital Pilling Tester is a device designed to assess the propensity of fabrics to form pills or fuzz on their surface. Pilling is the formation of small, fuzzy balls or clusters of fibers on the surface of a fabric due to friction, abrasion, or wear. The Digital Pilling Tester provides a standardized method to evaluate and compare the pilling resistance of different textiles.

Here are key features and aspects of a Digital Pilling Tester:

Principle of Operation:

Testing Standards:

Adjustable Parameters:

Digital Controls and Display:

Evaluation of Pilling:

Sample Preparation:

Applications:

Quality Control:

Data Recording:

Maintenance:

Assessing the pilling resistance of fabrics is crucial for manufacturers to produce high-quality textiles that meet consumer expectations for durability and appearance. Digital Pilling Testers provide a standardized and efficient method for evaluating and comparing the pilling performance of different materials.

Corrosion test chamber is a great laboratory test equipment widely used in metal...

Cyclic Corrosion Salt Spray Chamber manufactured by Sigma Machines – the world...

Sigma Machines CASS tester is designed keeping in mind the relevant tester stand...

Ensure the quality and durability of your materials with our reliable Double Hea...

SIGMA Machines is counted among the best salt spray chamber manufacturers in Ind...

Enhance your testing capabilities with our advanced digital pounding tester...

Enhance your foam testing process with our advanced PU foam Indentation Hardness...

Enhance your yarn quality control with our reliable and efficient yarn strength ...

Get accurate results with our Shear Fatigue Tester for PU Foam...

Ensure precise measurements of soft materials with our reliable thickness gauge...

Enhance your understanding of ball performance using our reliable Ball Resilienc...

Asian Water Absorption Tester is Water Resistance Tester For Sole Leather- (Perm...

Discover the ultimate laundry solution with Laundrometer Digital Model - the per...

Enhance your testing process with Test Template D and achieve accurate and relia...

Ensure the safety of children's toys with our reliable and efficient flammabilit...

The humidity test cabinet provides a sample with the humidity that the materials...

Ensure accurate results with our advanced Bundesmann Apparatus Tester for compre...

A Hot air oven is a great tool for manufacturers to accurately test materials i...

hydrostatic testing equipment used for testing lateral pipes is located within a...

Enhance belt quality control with our Belt Flex Tester, providing accurate and r...

Rockwell Hardness Tester models are suitable for accurately testing the hardness...

Martindale abrasion machine is suitable for testing the pilling degree and abras...

Adhesion Strength Tester serves the purpose of measuring the peelability or perm...

ASIAN Bursting Strength Tester Machine is especially useful for measuring the pa...

Achieve superior strength and resilience with our cutting-edge tensile strength ...

Enhance your quality control processes with our reliable Impact Tester, providin...

Ensure accurate measurements of your drapes' performance with our reliable Drape...

Glow Wire Test Equipment is an important testing equipment which is used in the ...

The heat distortion temperature of the polymer in the test is identified as the ...

Range: 2000 lbs with 1 lbs least count digital display Elongations: Up to 9...

Torque Tester for Bottle Caps is one of the important instruments to calculate t...

The “ASIAN” Universal testing machine provide a relatively inexpensive way...

Asian Melt Flow Index Tester helping evaluate the flow properties of melted plas...

Size of the Test Specimen: 40 X 15 mm Distance between edge of the Crease...

Box Compression Tester is used to measure the box compression strength (BCT), sh...

Enhance your material testing capabilities with the advanced Demattia Flex Teste...

Enhance your understanding of material properties with our Oscillating Disk Rheo...

Enhance your scientific experiments with our Specific Digital Gravity ...

Looking for an accurate and reliable IRHD Rubber Hardness Tester? Look no furthe...

Explore the world of direct reading specific gravity balance through our informa...

Enhance your testing efficiency and accuracy with our state-of-the-art universal...

Discover the Cone Calorimeter Tester: Enhance fire safety with accurate and reli...

Enhance your testing capabilities with a state-of-the-art dry sand abrasion test...

.jpg)

Get In Touch With Us

See How your Business Can benefit With

Sigma Machines

Get Estimated Quote